Induction Casting System Indutherm MC15

Walzbachtal (Germany)

Although this system is small, it can cast 60 to 100 g of material per melt cycle, depending on the density of the precious metal. The power is sufficient: the 3.5 kW induction generator melts the material in a few seconds. Heating occurs under vacuum, and casting is done under protective gas pressure, preventing oxidation and air inclusions. The temperature can reach up to 2000 °C, allowing the melting of platinum and white gold.

The system can also be used with the lid open, which is how I harden metals.

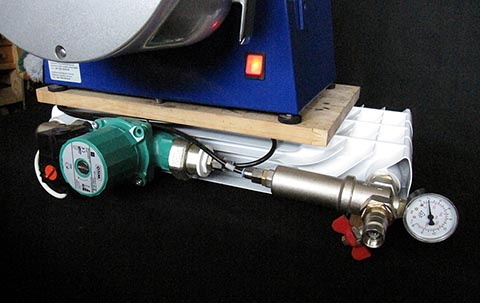

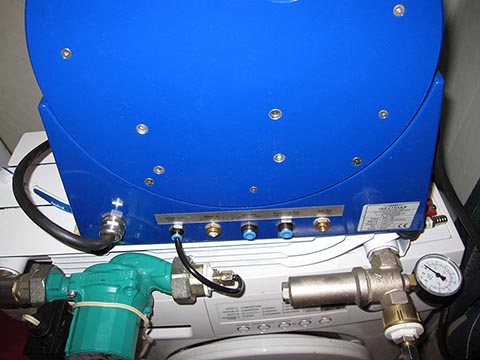

This furnace also requires a vacuum pump, protective gas (argon or nitrogen), and cooling for the induction generator. To be independent of a water supply and drainage, I built a closed cooling system using simple, readily available components from heating systems: pump, pressure gauge, filter with shut-off valve, radiator, and hoses. For longer operation, this cooling is somewhat limited, but it is sufficient for smaller work quantities. The cooling can be improved, for example, by adding a fan to the radiator or increasing the number of sections.